As one of the most well-known and respected brands in the ASHP

market, our heat pumps are suitable for small retail outlets and

commercial buildings as well as domestic properties.

Using efficient heat pump technology to deliver supreme comfort and

low operating costs, we have different series for air source heat

pumps such as for heating, swimming pool,spa, commercial buildings,floor, etc

Decades experience, over 300 patents, we are one of the largest

manufacturers of Swimming Pool Heat Pumps, House Heating Heat Pumps

and Heat Pump Water Heaters in China.

Leomon Technology provide high-end users integrated energy-saving solutions and

products including Swimming Pool Dehumidifiers, Swimming Pool Heat

Pumps, Room Heating&cooling Heat Pumps, hot water heat pump

solutions, Industrial and agriculture dryer Heat Pumps and

residential heat pump water heater home and abroad.

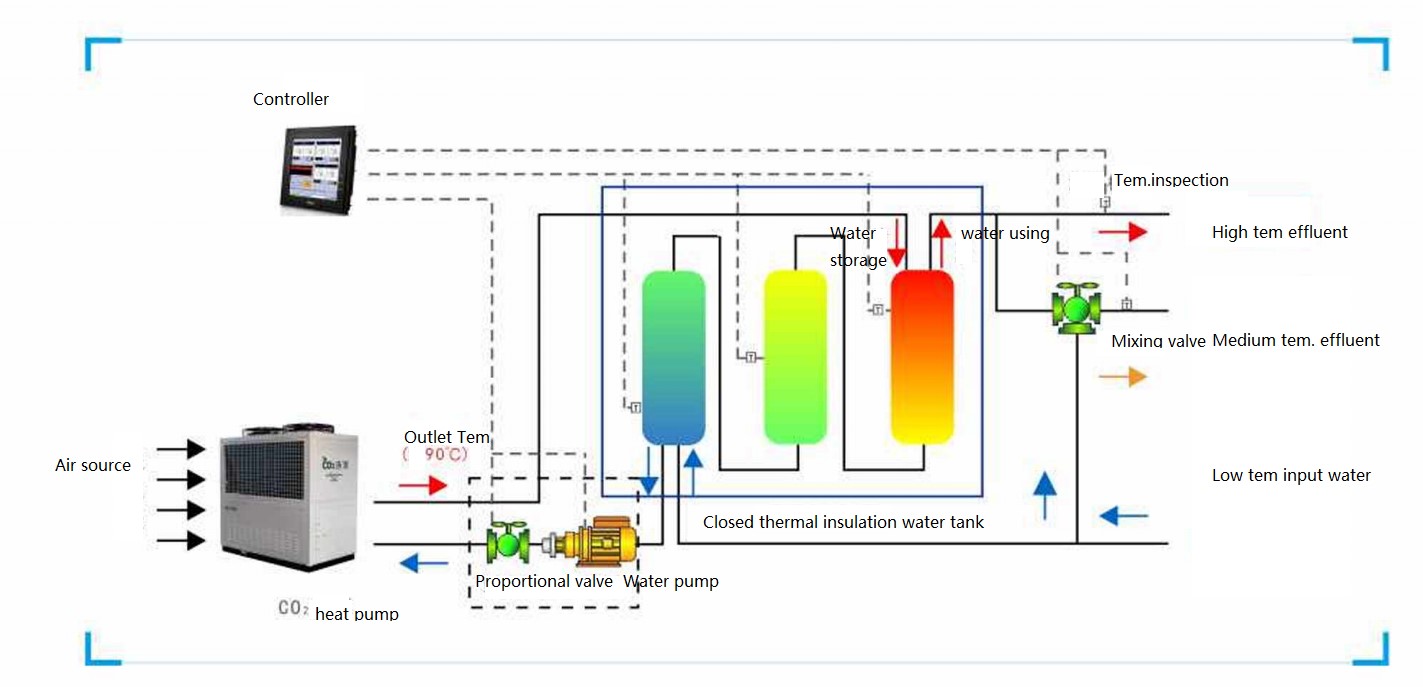

Strength products: High temperature outlet heat pump, up to 150

degree.

We also have CO2(R744) air source heat pump and water source heat

pump

Welcome to contact kelly@lnashp.com